Reading Time: <1 minutes

As global weather becomes more unpredictable due to the escalating effects of climate change, wind farm owners and operators are at risk of not capturing and responding to all repair requirements after an extreme weather event, which could result in costly operations and maintenance bills and unplanned downtime in the future. This is according to ONYX InSight, a leading provider of data analytics and engineering expertise to the global wind industry.

Extreme weather events are already having a direct impact on wind energy operations. In the recent Texas outage due to winter weather, the largest impact on energy supply was because of failures in equipment in nuclear, coal and gas facilities; wind production did decrease as a result of the storm in Texas earlier this month with approximately 18GW offline with ice affecting turbine blades. Research estimates that a coastal Texas wind farm also has a 15% chance of facing a hurricane in a 20-year lifespan and, with offshore wind hotspots US, China, and Taiwan subject to disruptive Typhoon seasons, the extent of this risk for the wind industry is only set to grow.

As a distributed energy source, across turbines in wind farms and frequently multiple farms across a region, there are some factors that mean wind power is less exposed to single weather events than other sources such as gas, coal, and nuclear power. For example, if an individual turbine within a fleet goes down, the power loss is minimal. However, as outdoor assets built in exposed conditions, wind is arguably more susceptible to the effects of weather and, if a whole fleet goes down due to icing, this can have the same level of impact as the loss of a coal fired station. This level of disruption was seen in August 2019 when Hornsea 1 went offline following a lightning strike with a loss of 800MW causing massive power outages across the UK.

With profit margins for wind energy production being squeezed due to reduced subsidy support, sky-high auction bids and lower energy prices, owners and operators cannot afford to waste money on unplanned downtime and unbudgeted maintenance costs. By adding more sensors to turbines, increasing the frequency of data collection from these sensors and, crucially, applying high-quality data analytics to this data, owners and operators can gain invaluable information on the effect of an extreme weather event on their entire fleet. This enables them to not only avoid unnecessary repairs expenditure but to protect assets that may have been invisibly affected from future, more critical damage.

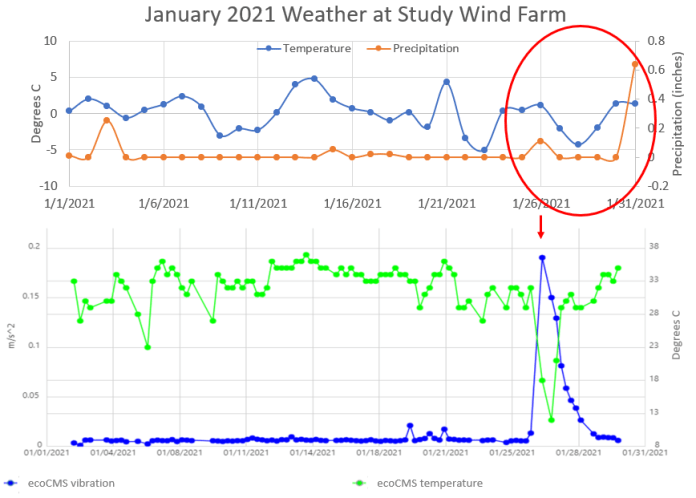

For example, a sudden drop in temperature and an increase in precipitation could lead to blade icing. As a result, an ecoCMS sensor can track this weather event as an increase in rotor imbalance vibration and a drop in temperature with its integrated thermocouple. Figure 1 below shows the Texas event detected by ecoCMS.

Figure 1. Texas event in late January 2021 caused blade icing which could be detected via vibration and temperature readings provided by ecoCMS

Ashley Crowther, Global VP, ONYX InSight, said “Often it’s difficult for asset owners to assess the full extent of the damage from an extreme weather incident and this can result in costly drone inspections ordered across entire fleets or damage going unnoticed on an asset until it gets much worse and more expensive to repair. For example, after a tornado incident in Texas, it was obvious that one turbine was irreparably damaged, but it was analysis of data from sensors across the fleet that showed several surrounding turbines had been affected too and needed repair. Using high-quality data analytics, ONYX InSight can determine what assets have experienced damage enabling proactive maintenance and limiting further inspection requirements.”

Ashley continues, “Most wind farm owners and operators already have monitoring technology installed. However, many are not taking full advantage of it. In the case of extreme weather events, we can increase the amount of data we are collecting from turbines to pinpoint exact times in changes in performance. This provides insights on how assets have been affected by the incident, for example whether a shutdown was necessary, and whether all assets in a fleet were affected equally – information crucial to support future operational decision making and to assess the need for investment in additional prevention technology such as heating systems.”

“Monitoring will develop to include more sensors and we will have the ability to integrate more data sources into turbine analytics such as weather data. The speed at which we can get data to the control panel will increase, as will our ability to flag warning signs. In the end, the more we know about a turbine and the more external data points we have, the more control and ability we have to maximise performance.”